Blind Rivets

Blind Rivets

Interested In Blind Rivets?

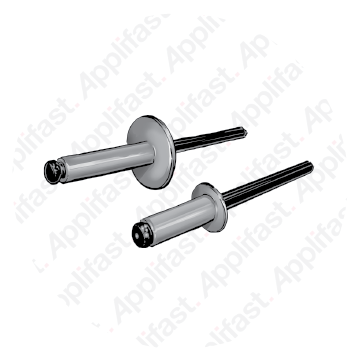

Blind rivets are ideal in applications where there is limited - or no - access to the blind side of the joint.

FAQs

Blind rivets are compatible with a wide range of materials including aluminum, steel, stainless steel, plastics, and composites. Their design allows for the joining of materials with different thicknesses and strengths. For true compatibility, it’s vital to select the right type of blind rivet for strength requirements, environmental conditions, the application, and material particularly when mixing metals to avoid galvanic corrosion.

Blind rivets are specifically designed for secure fastening in applications where access is only available from one side of the workpiece. They consist of a rivet body and a mandrel. When the mandrel is pulled through the body, it deforms the end of the rivet, creating a tight and secure joint. This process does not require access to the back side of the assembly, making blind rivets ideal for tight or hard-to-reach areas.

Yes, installing blind rivets requires a special tool known as a rivet gun or riveter. Rivet guns come in various forms, including manual, pneumatic, and battery powered models to accommodate different installation needs and environments.

Joint design, material selection, environmental conditions, load, and stress factors can all affect the lifespan of blind rivets. Rivets made from corrosion-resistant materials like stainless steel or those with protective coatings are better suited for harsh environments or outdoor use. The mechanical properties of the rivet should match the demands of the application to ensure long-term durability. Proper installation is also crucial.