Torque Measurement

Factories, production lines, and manufacturing plants all use a multitude of fasteners and assembly systems. They all require some measurement of torque. For years, torque has been the standard by which the strength of a joint was measured. This is flawed thinking that can lead to long-term issues for your output quality. Increased torque does not equal a stronger joint. Most joints today are either critical or safety critical and require accurate clamp load. We have tooling that will measure, test, audit, and calibrate.

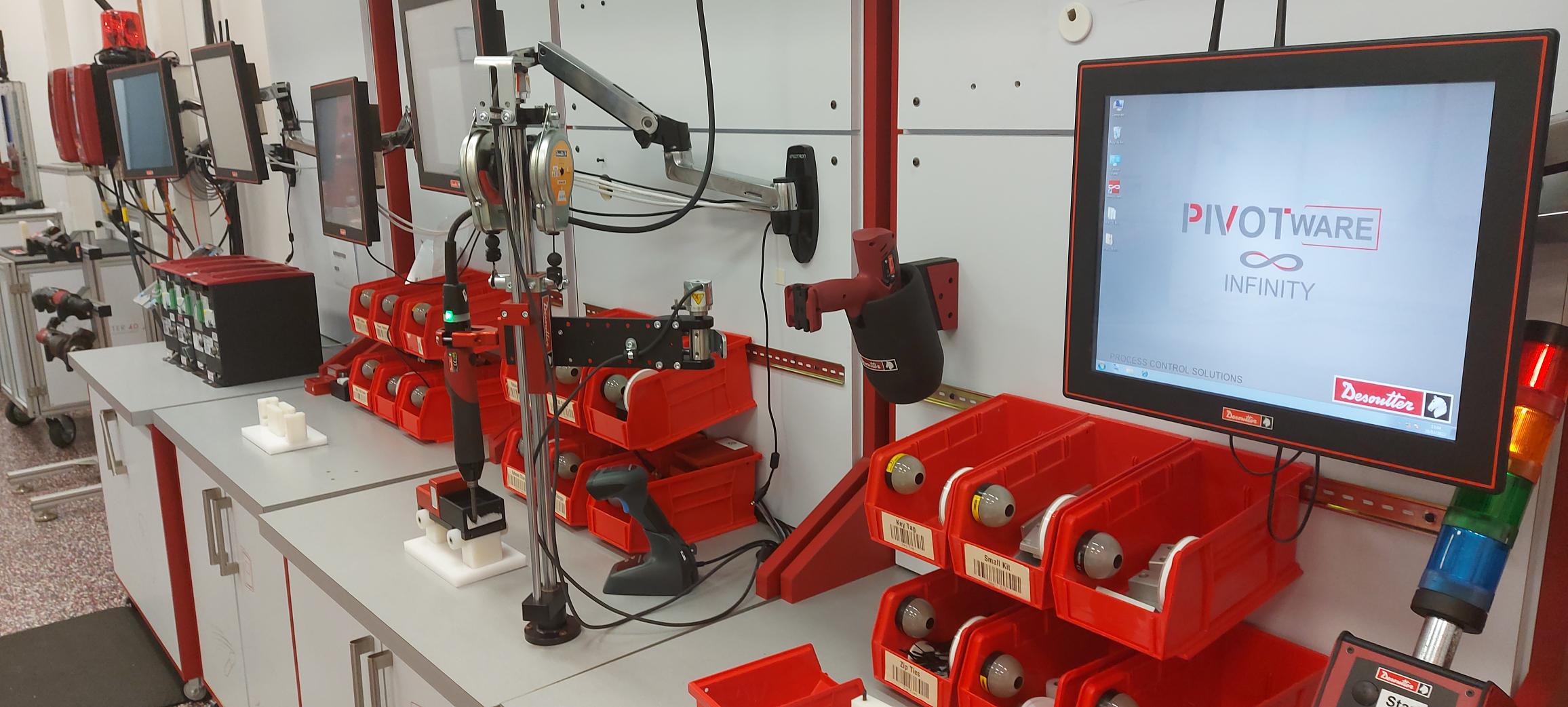

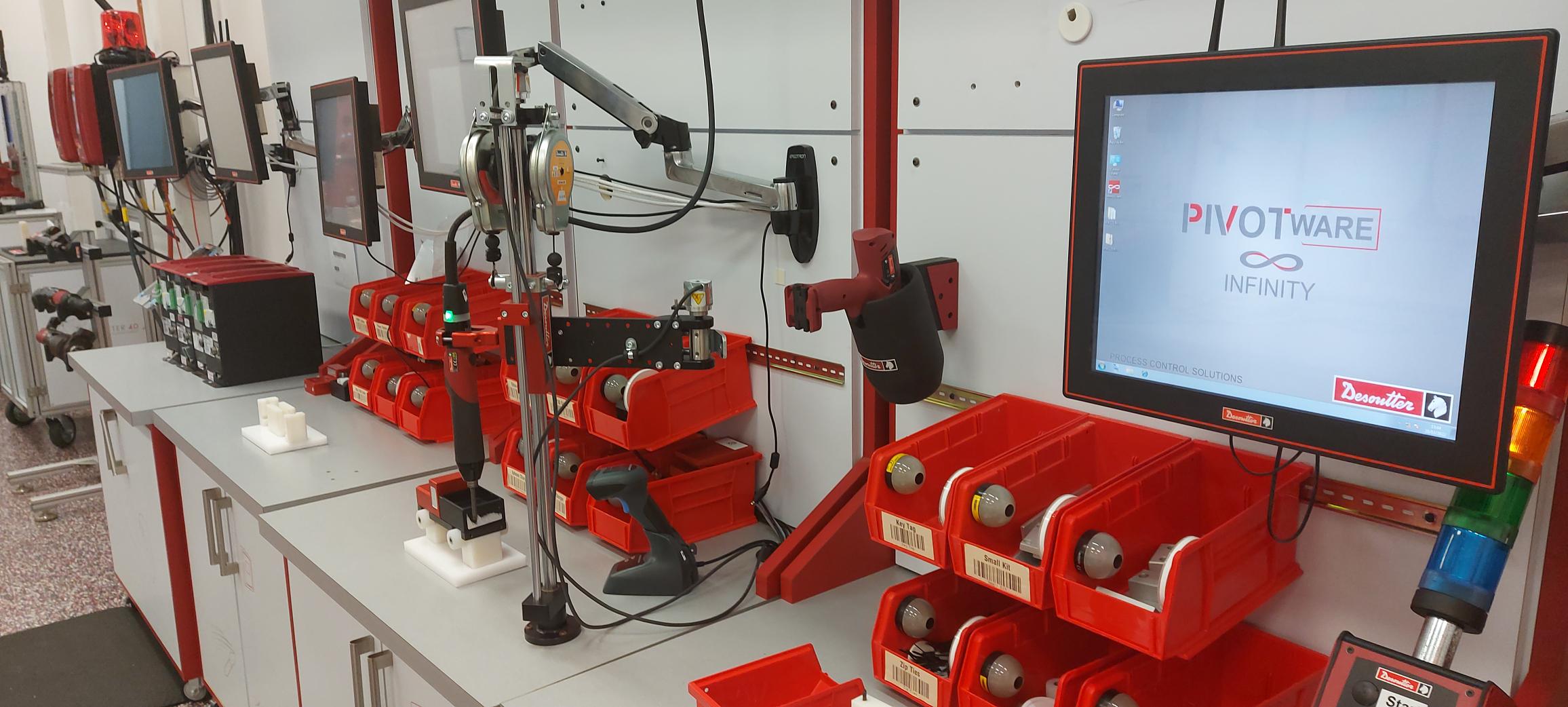

In an era of flexible manufacturing and priorities made to improve quality, zero-fault assembly and error proofing has become the new standard of value in efficient tightening for critical and safety-critical applications.

Equipment

Faliure is not an option. Testing and checking your torque requirements is the differnce in quality production. Applifast can provide your torque measuremnet equipment for electric and pneumatic tools allowing for full traceability and precision quality.

Transducers

Torque transducers are ideal for testing and measuring the actual torque applied and the angular roation of the fastener under production enviroments. Applifast can supply you with rotary and stationary type of transducers suitable for measurment continuous drive, impulse and torque wrenches.

Wrenches

When proper torque measurement is needed, a torque wrench can provide your fastening assembly the correct torque. Results by an electronic window or click. Applifast can assist you with what torque wrench suits your needs or application best.

Accessories

From joint simulators, joint kits, torque testers to software, Applifast has you looked after. We can provide you the complete solution including programming, traceability and production data.

Test Benches

Mobile auditing, mobile torque testing, and capability benches allow for a flexible and versatile solution, high quality performance on the production line. The benches allow for simulation, and can be set up in the same way as the fastener is on the production line. Configuration from 1Nm to 1000Nm. Benches can also be set up to test the torque ranges of your tools right on the production line.

Critical and safety critical fastening is too important to not have the right tools. We are dedicated to meeting the highest quality assurance standards and all demands required to ensure error proofing in each and every adapted application.

FAQs

Electronic torque measurement tools offer significant advantages over manual torque measurement methods. Electronic tools provide precise torque measurements, reducing the margin of error compared to manual methods. Electronic torque tools often alert the user when the correct torque is reached, minimizing the risk of over-torquing or under torquing, and therefore improving consistency. Many electronic torque tools can record and store data about the torque applied to each fastener, offering traceability for quality control in industries where compliance with standards is critical.

Proper torque measurement is fundamental to the longevity and reliability of fastened joints. Too much torque can lead to stress, deformation, or even breakage of fasteners and materials. Not enough torque can result in loose fasteners, leading to joint failure, leaks, or vibrations. Correct torque application ensures loads are evenly distributed across all fasteners, reducing the risk of premature wear or failure in any single fastener and enhancing the overall reliability of the joint.

Yes! Our torque measurement tools can be integrated into automated production lines to enhance efficiency, accuracy, and productivity. Tools are designed with compatibility in mind, and we can customize solutions to specific requirements. We have tools that offer remote monitoring and control capabilities, as well as data integration.

We carry a complete range of torque equipment (micro-torque to +1000 Nm), torque transducers, torque wrenches, torque screwdrivers, torque testers, torque analyzers, and accessories - you’ll find them all here:

https://shop.applifast.com/collections/torque-measurement

We ensure accuracy and reliability through calibration and certification, investing in advanced technology, testing, validation, and compliance with industry standards. We also provide user-training, support, and engage in continuous improvement initiatives to enhance the accuracy, reliability, and performance of our torque measurement equipment over time.