Lockbolts

LockBolts

Interested In Lockbolts?

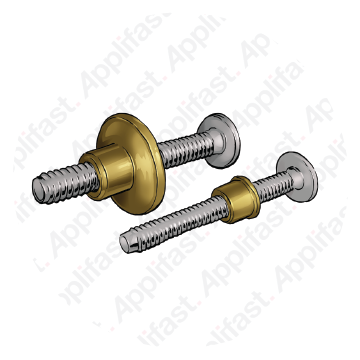

Lockbolts are two-piece fastening system, consisting of a hardened metal pin and metal collar which swages into the grooves of the pin. This forms a specific measured clamp force to hold assembled parts together.

FAQs

Lockbolts provide immediate, high-strength, vibration resistant fastening, making them ideal for applications where durability and speed are critical. They often install in less than two seconds with consistent clamp force and high shear strength. Unlike traditional bolts, there's no need for torque wrenches or retightening.

Yes, lockbolts are well-suited for use in outdoor environments. Lockbolts are available in a variety of materials including stainless steel and aluminum, which offer inherent corrosion resistance. With proper material selection and, if necessary, additional coatings or treatments, lockbolts can effectively resist corrosion.

Lockbolts come in a wide range of sizes ranging from very small diameters for light applications to large diameters for heavy-duty uses. Common materials include high-strength steel, stainless steel, and aluminum. There is a lockbolt for virtually any fastening challenge, from aerospace and automotive to construction and heavy machinery. In addition to different sizes and materials, lockbolts may also come with various head styles (e.g. domed, countersunk) and locking mechanisms (e.g. collar, pintail) to suit specific installation and performance requirements.

Environmental conditions can significantly impact the performance of lockbolts as they can affect the material’s properties, corrosion resistance, and the overall integrity of the joint. Some key environmental factors to consider include moisture and humidity, temperature extremes, chemical exposure, UV radiation, vibration, and shock. It’s important to select the appropriate lockbolt material and finish based on the specific environmental conditions of your application.

Lockbolts can be found in a wide range of applications across various industrial settings due to their reliability, strengths, and ease of installation. Some common applications include transportation, railroad, marine and offshore, construction and infrastructure, energy, mining, manufacturing and fabrication, and defense and aerospace. These are just a few examples of lockbolts in industrial settings. Their versatility, reliability, and durability make them a preferred choice for joining metal components.